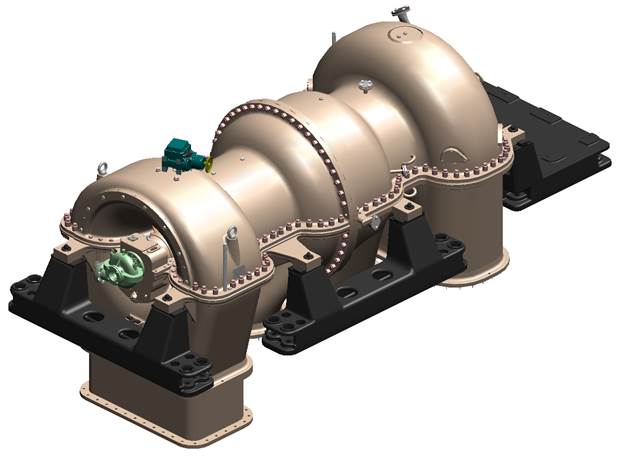

Gas process turbine GTT-9 is based on the modernized gas turbine GTT-3М. Modern approaches in engineering have allowed to get the required parameters with less number of stages and a unit in more reliable arrangement. GTT-9 is used in production lines of low concentration nitric acid UKL-7.

Specification

|

Parameyer |

GTT-9 |

GTT-3М |

|---|---|---|

|

Air flow rate at inlet to compressor, t/hours |

122,6 |

103 |

|

Air flow supplied to process, t/hour |

102,6 |

94,5 |

|

Air pressure after compressor, MPa |

0,737 |

0,25 |

|

Air temperature after compressor, °С |

280 |

175 |

|

Adiabatic efficiency of compressor, % |

86,6 |

86 |

|

Number of stages in compressor |

9 |

17 |

|

Power of compressor, MW |

8,93 |

7 |

|

Gas temperature before turbine, °С |

680 |

700 |

|

Turbine efficiency, % |

90,0 |

85 |

|

Power of turbine, MW |

9,0 |

7,25 |

|

Number of stages in turbine |

3 |

7 |

|

Rotor rotational speed, rev./min |

7500 |

5100 |

|

Consumption of fuel gas, kg/hour |

900 |

2000 |

|

Specified lifetime, hours |

150 000 |

130000 |

Competitive advantages and design features

- Increasing efficiency by minimum 5%

- Increasing the operation life by more than 40%

- Reduction of repair work labor by 50%

- High fuel efficiency (necessity of natural gas consumption for the same amount of nitric acid production is on 10% less then in GTT-ЗМ)

- Changing the airflow rate through the blades in the range 85-105% of rated capacity due to rotary inlet guide vanes

- Gaining of required compression ratio in 9 compression stages instead of 17

- Driving the compressor with n=7500 rev./min obtaines with three turbine stages

- Maximum temperature of disk’s projections does not exceed 360°C

- Ensuring efficiency of turbine at the temperature by inlet gas up to 800°C

- Increasing the blades service life more than double owing to nano-structured covering of turbine blades

- Availability of temperature reserve before the turbine to force parameters and to operate the unit in a wide range of atmospheric conditions witn keeping high performance and pressure

- Using the new sliding bearings with metal-fluoroplastic band for easy replacement and repair

Delivery set composition

- Turbo-compressor GTT-9 in the updated case

- Start up electric motor with variable frequency control

- Hydraulic coupling (start up electric motor – rotor)

- Frame for start up electric motor

- Kit of mounting components

- SPTA set

- Package of maintenance documentation

- Automatic control system (option)

- Oil system made as a separate oil module (option)