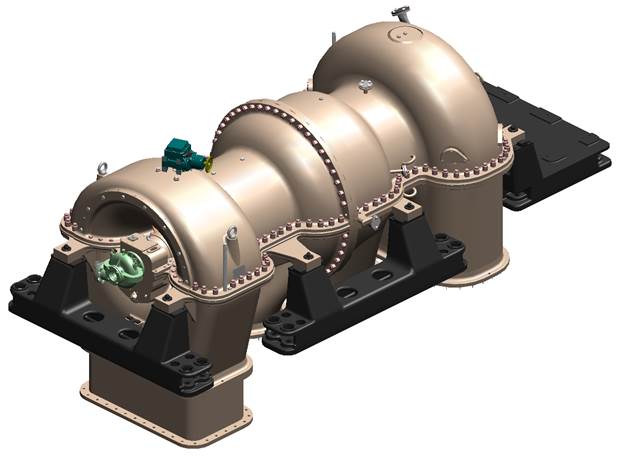

Gas Process Turbine GTT- 9 based on the modernization of the installation GTT-3M with current approaches in the design, allowing to get the required parameters in a much smaller number of steps and a more reliable design concept. Installation GTT- 9 used to produce nitric acid in the ehnergotehnological lines UKL -7.

Competitive advantages and design features

- Increased efficiency of at least 5%

- Increased service life of more than 40 %

- Reducing the complexity of repair work on 50 %

- A high efficiency fuel ( natural gas consumption required to produce the same amount of nitric acid is reduced by 10 % compared to the GTT- 3M)

- Changing the flow of air through the blades in the range 85-105 % of the rated capacity, due to the rotary inlet guide vanes

- Ensure the necessary degree of compression stages 9 instead of 17

- Ensuring compressor drive for n = 7500 r / min with three turbine stages

- Maximizing the temperature protrusions discs max 360 °C

- Ensuring efficiency turbine at the inlet gas to 800 °C

- Increasing the blade service life more than 2 times, through the use of nano-structured coating turbine blading

- Having a stock temperature before the turbine for forcing parameters and operation of a wide range of atmospheric conditions while maintaining high productivity and pressure

- The presence of new sliding bearings with metal-fluoroplastic tape for easy replacement and repair of sliding bearings

Specification

|

Parameters |

Value |

|---|---|

|

Airflow in the compressor, m / h |

122,6 |

|

Air consumption technology t / h |

102,6 |

|

The air pressure of the compressor, MPa |

0,737 |

|

The air temperature of the compressor, °C |

280 |

|

Adiabatic compressor efficiency,% |

86,6 |

|

Compressor stages |

9 |

|

Power compressor , MW |

8,93 |

|

The gas temperature at the turbine inlet, °C |

680 |

|

Turbine efficiency, % |

90,0 |

|

The power turbine, MW |

9,0 |

|

Number of turbine stages |

3 |

|

Rotational speed, rev/min |

7500 |

|

Fuel gas consumption, kg/h |

900 |

|

Specified life, h |

150 000 |

Delivery

- Turbocharger GTT- 9 in the modified housing

- Starting electric motor with frequency regulation

- Hydraulic coupling ( starter motor - rotor)

- The transitional frame for starting the motor Set of mounting parts

- Set of spare parts

- Set of operational documentation

- The automatic control system (optional)

- The oil supply system is designed as a separate lube (optional)

e-mail: export@dalenergomash.ru [1]